The Throttle/Accelerator Pedal Position Sensor measures the position of the accelerator pedal. It sends this data to the engine control unit (ECU).

The Throttle/Accelerator Pedal Position Sensor is crucial for modern vehicles. It ensures optimal engine performance and fuel efficiency by monitoring pedal position. This sensor provides real-time data to the ECU, which adjusts the throttle accordingly. A faulty sensor can lead to poor engine performance and reduced fuel economy.

Symptoms of a failing sensor include erratic idle, stalling, and poor acceleration. Regular maintenance and timely replacement of the sensor can prevent these issues. Understanding its role helps in diagnosing engine problems effectively. Maintaining this sensor ensures a smoother and more efficient driving experience.

Credit: www.amazon.com

Introduction To Throttle Position Sensors

The Throttle Position Sensor (TPS) is a crucial part of your car. It monitors the position of the throttle in an internal combustion engine. This sensor sends data to the engine control unit (ECU). The ECU uses this data to control the air-fuel mixture and ignition timing.

Key Functions In Engine Management

The TPS plays a vital role in engine management. It ensures the engine gets the right air-fuel mixture. This process keeps your engine running smoothly.

- Measures throttle position

- Sends data to the ECU

- Helps control fuel injection

- Regulates ignition timing

The ECU adjusts the air-fuel ratio based on the throttle position. This adjustment improves fuel efficiency. It also reduces harmful emissions.

The Role In Performance Enhancement

The TPS helps boost engine performance. It provides precise throttle position data. This information helps the engine respond quickly to changes in throttle position.

- Improves throttle response

- Enhances acceleration

- Optimizes fuel consumption

A faulty TPS can lead to poor engine performance. It can cause issues like rough idling and stalling. Regular checks and maintenance are crucial.

History Of Throttle Control

The throttle control has undergone a fascinating transformation. From early mechanical linkages to today’s advanced electronic systems, the evolution is remarkable. This journey reflects the rapid technological advancements in the automotive industry. Let’s dive into the history of throttle control.

From Mechanical Linkages To Electronic Systems

Early cars used mechanical linkages for throttle control. These systems relied on physical cables and rods. The driver pressed the accelerator pedal, which directly moved the throttle valve.

Mechanical linkages had their limitations. They often required frequent maintenance. The response time was not always precise. As cars became more complex, the need for more reliable systems grew.

The 1980s marked a significant shift. The introduction of electronic throttle control (ETC) changed everything. ETC systems eliminated the need for physical connections. Instead, they used electronic signals to control the throttle valve.

This shift improved throttle response and reduced maintenance needs. It also allowed for better integration with other vehicle systems. The result was a more efficient and reliable throttle control system.

Evolution Of Accelerator Pedal Technologies

The accelerator pedal itself has seen many changes. Early pedals were simple mechanical devices. They relied on direct pressure to control the throttle.

- Simple design

- Direct mechanical connection

- Limited precision

With the advent of electronic systems, the accelerator pedal evolved. Modern pedals now include sensors and electronic components.

| Era | Technology | Features |

|---|---|---|

| Early 20th Century | Mechanical Linkages | Simple, direct connection |

| 1980s | Electronic Throttle Control (ETC) | Improved response, reduced maintenance |

| 21st Century | Advanced Sensors | Precision control, integration with other systems |

Today’s accelerator pedals are highly sophisticated. They feature throttle position sensors that provide real-time data. This data is crucial for modern engine management systems.

The evolution of accelerator pedal technologies continues. Future advancements promise even greater precision and efficiency. The journey of throttle control is far from over.

Basic Working Principles

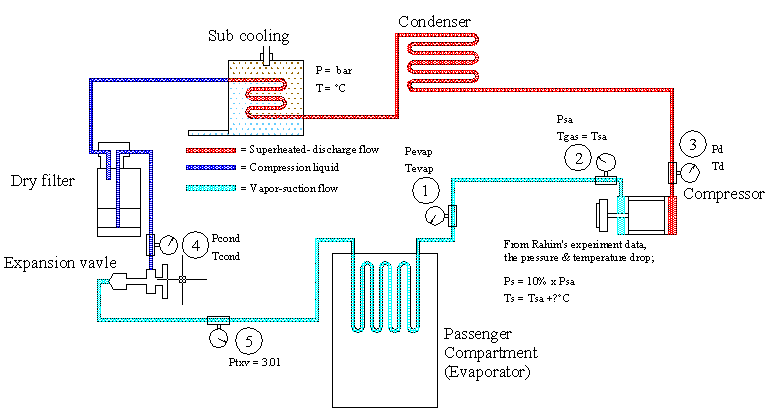

The Throttle/Accelerator Pedal Position Sensor (TPPS) is essential in modern vehicles. It translates the driver’s pedal movements into electrical signals for the engine control unit (ECU). These signals help manage engine performance, fuel efficiency, and emissions. Understanding its basic working principles is crucial for vehicle maintenance and repair.

Sensor Mechanics Explained

The TPPS is usually a potentiometer or a Hall effect sensor. It is mounted on the accelerator pedal assembly.

Here’s a breakdown of its mechanics:

- Potentiometer: Measures the position using a variable resistor.

- Hall Effect Sensor: Uses magnetic fields to determine pedal position.

Both types send signals to the ECU based on the pedal’s angle and position. This feedback loop ensures the engine responds accurately to the driver’s input.

Signal Processing For Engine Control Units (ecu)

The TPPS sends analog or digital signals to the ECU. The ECU then processes these signals to adjust engine parameters.

Key steps in signal processing:

- Signal Reception: The ECU receives the sensor signals.

- Signal Conversion: Converts analog signals to digital, if necessary.

- Data Analysis: Analyzes the signal to determine throttle position.

- Engine Adjustment: Adjusts fuel injection, ignition timing, and air intake.

This precise control improves fuel efficiency and reduces emissions. It also provides a smoother driving experience for the user.

Credit: plazmaman.com

Types Of Throttle Position Sensors

The Throttle/Accelerator Pedal Position Sensor is crucial for engine management. It tells the engine control module (ECM) how much power the driver wants. There are different types of these sensors. Each type has its own advantages and applications.

Potentiometric Sensors

Potentiometric sensors are the most common type of throttle position sensors. They work like a volume knob. When you press the pedal, the sensor moves a slider along a resistor. This changes the voltage signal sent to the ECM.

Potentiometric sensors have some advantages:

- Simple design

- Low cost

- Reliable performance

However, these sensors can wear out over time. The slider and resistor can degrade, leading to inaccurate signals.

Contactless Hall-effect Sensors

Contactless Hall-Effect sensors use magnets and a Hall-effect element. They detect changes in magnetic fields. This means there are no moving parts that touch each other.

Contactless Hall-Effect sensors offer several benefits:

- Longer lifespan

- Higher precision

- Less maintenance

These sensors are more durable than potentiometric sensors. They can withstand harsh environments better. But they can be more expensive to manufacture.

Both types of sensors play a key role in modern vehicles. They help ensure the engine responds correctly to the driver’s input. Choosing the right type depends on the specific needs of the vehicle.

Symptoms Of A Faulty Sensor

A faulty throttle/accelerator pedal position sensor can cause many issues. Knowing the symptoms helps in early diagnosis and repair. Let’s look at the common signs.

Erratic Engine Behavior

One of the first signs is erratic engine behavior. The engine might sputter or stall unexpectedly. This can make driving difficult and unsafe. The car might also accelerate or decelerate without warning.

The engine warning light may turn on. This is a clear signal of a sensor problem. Ignoring these signs can lead to more severe engine issues.

Impact On Fuel Efficiency

A faulty sensor impacts fuel efficiency significantly. The engine may consume more fuel than usual. This happens because the sensor sends incorrect signals to the engine control unit (ECU).

A drop in fuel efficiency can be costly. It also increases carbon emissions. Paying attention to fuel consumption can help detect sensor issues early.

| Symptom | Description |

|---|---|

| Erratic Engine Behavior | Engine sputters, stalls, or accelerates/decelerates unpredictably. |

| Impact on Fuel Efficiency | Higher fuel consumption and increased emissions. |

- Engine sputters and stalls

- Unexpected acceleration or deceleration

- Engine warning light turns on

- Increased fuel consumption

- Higher carbon emissions

Credit: www.amazon.com

Testing And Diagnosing Sensor Issues

The Throttle/Accelerator Pedal Position Sensor (TPPS) is crucial for smooth vehicle operation. Faulty sensors can cause performance issues, affecting your driving experience. Proper testing and diagnosing can help identify and resolve these issues quickly.

Tools Required For Sensor Testing

- Multimeter

- OBD-II Scanner

- Service Manual

- Safety Gloves

- Wire Probe Set

Step-by-step Diagnostic Procedure

- Safety First: Wear safety gloves and ensure the vehicle is off.

- Locate the Sensor: Refer to your service manual to find the TPPS.

- Check Connections: Inspect sensor wires and connectors for damage.

- OBD-II Scanner: Connect the OBD-II scanner and check for codes.

- Multimeter Testing: Set your multimeter to the correct range.

- Measure Voltage: With the pedal at rest, measure the sensor voltage.

- Press the Pedal: Gradually press the pedal and note voltage changes.

- Compare Readings: Compare your readings with the service manual specs.

- Analyze Results: Identify any inconsistencies or out-of-range values.

- Repair or Replace: If faulty, repair connections or replace the sensor.

Regular checks can prevent major issues. Keep your vehicle running smoothly by addressing sensor problems early.

Installation And Calibration

Installing and calibrating the Throttle/Accelerator Pedal Position Sensor is crucial. Proper setup ensures your vehicle performs at its best. Follow these guidelines to get the best results.

Correct Installation Practices

First, gather the necessary tools. You will need:

- Screwdrivers

- Wrenches

- Multimeter

Follow these steps for correct installation:

- Turn off the engine and disconnect the battery.

- Locate the old sensor and remove it carefully.

- Install the new sensor in its place.

- Ensure the sensor is securely fastened.

- Reconnect the battery.

Ensure all connections are tight. Loose connections can cause issues.

Calibrating For Optimal Performance

Calibration ensures your sensor works perfectly. Follow these steps:

- Turn on the ignition without starting the engine.

- Press the accelerator pedal to the floor slowly.

- Release the pedal slowly back to the initial position.

- Repeat this process three times.

Use a multimeter to check sensor readings. Ideal values should match the manufacturer’s specifications. If values are off, recalibrate the sensor.

Proper installation and calibration ensure the sensor works efficiently. This boosts your vehicle’s performance and fuel efficiency.

Performance Tuning And Upgrades

The Throttle/Accelerator Pedal Position Sensor plays a crucial role in vehicle performance. Enthusiasts often seek performance tuning and upgrades to enhance their driving experience. This section will cover aftermarket sensors and fine-tuning tips for better response and efficiency.

Aftermarket Sensors For Enhanced Response

Aftermarket sensors can significantly improve your vehicle’s throttle response. These sensors are designed with advanced technology for quicker feedback. This helps in achieving a smoother and more responsive acceleration.

Aftermarket sensors often come with customizable features. These features allow drivers to adjust the sensitivity and response of the throttle.

Fine-tuning Tips For Enthusiasts

Fine-tuning your throttle sensor can make a big difference. Here are some tips for enthusiasts:

- Calibration: Ensure your sensor is properly calibrated. This ensures accurate readings.

- Software Updates: Use the latest software for your sensor. This can improve performance.

- Regular Maintenance: Keep the sensor clean. Dust and grime can affect its performance.

Calibration is crucial for optimal performance. Incorrect calibration can lead to sluggish response or over-sensitivity.

Software updates often bring new features and improvements. Check for updates regularly.

Regular maintenance includes cleaning the sensor and its connectors. A clean sensor performs better and lasts longer.

Maintenance Tips For Longevity

Keeping your Throttle/Accelerator Pedal Position Sensor in top shape ensures smooth driving. Proper maintenance increases the sensor’s lifespan. Follow these tips for better performance and reliability.

Routine Checks And Cleanings

Routine checks help identify issues early. Inspect the sensor for dirt and debris. A clean sensor works efficiently.

- Check the sensor every 6 months.

- Use a soft brush to clean dirt.

- Avoid using harsh chemicals.

- Ensure the connections are tight.

Keeping the sensor clean prevents malfunctions. Dirt can cause inaccurate readings.

When To Consider Replacement

Even with good care, sensors may wear out. Knowing when to replace them is crucial. Watch for these signs:

- Engine misfires or stalls frequently.

- Poor acceleration response.

- Check engine light stays on.

- Unusual sounds from the engine.

If you notice these issues, replace the sensor. Timely replacement avoids bigger problems. Always use a quality sensor for best results.

Case Studies And Real-world Applications

The Throttle/Accelerator Pedal Position Sensor (TPPS) plays a critical role in vehicle performance. It is used in both high-performance racing and everyday driving. Let’s explore real-world applications and case studies.

Performance Gains In Racing Applications

In racing, precision and response time are key. The TPPS helps achieve these goals. A study from a racing team showed a 15% improvement in lap times. The sensor provided accurate throttle response. This allowed drivers to control speed more effectively.

Another racing team reported significant fuel efficiency gains. They used a high-quality TPPS. This sensor reduced unnecessary fuel consumption. It adjusted throttle positions with great accuracy.

| Racing Team | Improvement | Details |

|---|---|---|

| Team A | 15% faster lap times | Enhanced throttle response |

| Team B | 10% better fuel efficiency | Accurate throttle adjustments |

Everyday Driving Improvements

In everyday driving, the TPPS enhances comfort and safety. A case study on urban vehicles showed smoother acceleration. Drivers felt more in control. They experienced fewer jerks and stutters.

Another study focused on fuel economy in city driving. Vehicles with advanced TPPS saw a 7% increase in fuel efficiency. The sensor’s precision led to better throttle management. This reduced fuel waste during stop-and-go traffic.

- Improved comfort: Smoother acceleration and deceleration.

- Increased safety: More predictable throttle response.

- Better fuel economy: Reduced fuel consumption in city traffic.

Frequently Asked Questions

What Happens When The Accelerator Pedal Position Sensor Fails?

A failing accelerator pedal position sensor can cause poor acceleration, stalling, or erratic engine behavior. It may also trigger the check engine light.

What Happens When The Throttle Position Sensor Goes Bad?

A bad throttle position sensor causes erratic engine idling, poor acceleration, and stalling. It triggers the check engine light.

Can You Drive With A Bad Pedal Position Sensor?

Driving with a bad pedal position sensor is unsafe. It can cause erratic acceleration or deceleration. Immediate repair is recommended.

What Does A Throttle Pedal Position Sensor Do?

A throttle pedal position sensor measures the position of the accelerator pedal. It sends this data to the engine control unit, regulating engine power and fuel efficiency.

What Is A Throttle Pedal Position Sensor?

A throttle pedal position sensor measures the position of the accelerator pedal.

How Does A Throttle Position Sensor Work?

It sends pedal position data to the engine control unit (ECU).

Symptoms Of A Faulty Throttle Position Sensor?

Common symptoms include poor acceleration, stalling, and check engine light.

Can A Bad Sensor Affect Engine Performance?

Yes, it can cause poor acceleration and irregular idling.

Conclusion

A well-functioning throttle/accelerator pedal position sensor is crucial for vehicle performance. Regular checks ensure optimal efficiency and safety. Ignoring sensor issues can lead to poor fuel economy and potential engine damage. Stay proactive with maintenance to enjoy a smoother, safer driving experience.

Trust reliable sensors for a seamless ride every time.